Kleemann outlines electric mobile crushing requirements

1 天前 In the electrified version, it has an average current consumption of 302 kW per operating hour. The maximum power requirement is 542 kilowatts,” said Tobias Böckle, Head of Product Management at Kleemann. “The energy requirement must first be provided by the

consulter en ligne

Energy consumption of a laboratory jaw crusher during

2023.12.1 Power consumption and therefore efficiency of crushing equipment are becoming increasingly important mainly due to the continuous and rapid increase of energy

consulter en ligne

Modeling and Improving the Efficiency of Crushing Equipment

2023.5.16 Thus, the urgency of using crushers in mining and processing plants is clear, so it is relevant to find ways to optimize their operation and reduce energy consumption. This

consulter en ligne

Requirements and Energy Consumption of Crusher Plants

2024.3.30 In addition to power requirements, crusher plants also consume energy during operation, primarily through the crushing process itself and auxiliary equipment such as

consulter en ligne

Energy consumption values of each crusher per tonne

This paper presents a different approach to determine the energy consumption during comminution. The energy required for crushing rocks was obtained by direct measurement of

consulter en ligne

Modeling and Improving the Efficiency of Crushing Equipment

2023.6.30 The subject of this study is crushing equipment. It is a complex of units designed to reduce the fraction of ore and non-metallic solid materials. It is also designed to make them

consulter en ligne

Cement Industrial Process: Modeling and Optimization

2019.9.9 The crusher specific electrical energy represents the energy consumed by the different elements of the crusher to produce a ton of cement. The major equipment that

consulter en ligne

The Energy-Saving Control Criterion for Impact Crushing ...

2023.11.12 equipment make possible to reduce the specific electrical energy consumption up to 15% and this is the basis for using a criterion based on specific costs in control systems

consulter en ligne

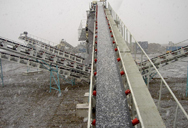

All-electric operation of mobile crushing and screening plants

2024.9.18 A sample plant train includes the MOBICAT MC 120 PRO jaw crusher, MOBICONE MCO 110 PRO cone crusher, and MOBISCREEN MSC 953 EVO screen

consulter en ligne

Study of the Energy-Power Parameters of the

2023.3.6 Using the method of equivalent power required for the electric motor drive of the crushing machine at the steady mode of operation and basic laws of general mechanics, we explain the following: the dependences of the

consulter en ligne

Energy Efficiency Measurement of Mechanical Crushing

2024.6.28 Mechanical crushing equipment holds a pivotal position in industrial production, finding widespread application in various sectors such as building materials, chemicals, metallurgy, and mining [1,2,3,4].As global awareness of energy conservation and emission reduction continues to grow, enhancing the crushing efficiency of mechanical grinding

consulter en ligne

Crushing and Screening Handbook - AusIMM

2021.6.24 9 Automation and Electrical Components 9 Crusher Automation 9 Visiorock 10 Wear Parts - Crushers 11 Customer Service 12 Standards and Technical Infromation ... experience of crushing equipment and crush-ing processes, has developed an expert service off ering aimed at improving the reliability and productivity of customer operations. Metso’s ...

consulter en ligne

Energy consumption of a laboratory jaw crusher during

2023.12.1 Power consumption and therefore efficiency of crushing equipment are becoming increasingly important mainly due to the continuous and rapid increase of energy costs and efforts to minimise CO 2 emissions (Tromans, 2008, Legendre and Zevenhoven, 2014).In order to meet the Paris Climate Agreement goals, recycling should be maximized by 2050

consulter en ligne

Assessing the energy efficiency of a jaw crusher - ScienceDirect

2014.9.1 The aim of the present work is to understand the reasons for inefficiency and to improve the efficiency of comminution machinery. Bond’s Work index coefficients cover almost the entire range of particles to be processed using commercial equipment [4].With this theory, the energy requirements are based on experimental shaft energy measurements of comminution

consulter en ligne

Assessing the energy efficiency of a jaw crusher - ScienceDirect

2014.9.1 It is well known and taken for granted that the efficiency of energy use by comminution (i.e. breaking, crushing, grinding) equipment is very low, typically less than 10%. Most of the process input power is dissipated as heat and noise and ineffective deformation of the material to be processed and the device itself.

consulter en ligne

Equipment energy consumption: how to measure? - Squair

2023.2.14 Only with this knowledge, from efficient data collection, the company will be able to achieve energy efficiency of the equipment. How to calculate the energy consumption of equipment? With the right resources, calculating energy consumption can be a straightforward task. The calculation is based on the power of the equipment (kWh) and the time ...

consulter en ligne

Crushing Plant Design and Layout Considerations - 911

2024.9.24 design, so that they can identify ways of reducing overall electrical power consumption. • Electronic control of crusher discharge opening and feed rate. With adjustment of a ... • Operators have always dreamed of reducing the need for crushing equipment; when SAG mills were first introduced, it was hoped that they would eliminate secondary ...

consulter en ligne

MINING ENERGY CONSUMPTION 2021 - ceecthefuture

From the breakdown of energy consumption, it was found that comminution accounts for 25% of final energy consumption of an “average” mine site. Diesel in mobile equipment accounts for 46%, electricity in mining (ventilation) 15% and other electricity 14%. These are averages based on the different splits of energy consumption that were

consulter en ligne

All-Electric Mobile Crushing and Screening Plants

2024.9.10 Many companies operating mobile crushing and screening plants already have transformers on site that adapt voltage to the required levels, such as low voltage for plant operation. Once you calculate the power requirements for your electric crushing and screening equipment, it's essential to ensure the existing transformer is adequate.

consulter en ligne

Energy and Power Consumption Calculator - kWh Calculator

3 天之前 The following example shows how to calculate your electrical energy and power consumption “Wh” and “kWh” on a daily, monthly and annual basis. To do this, you must know the wattage rating of the device in watts (or voltage x current rating = power rating) and the operation time of the appliance in hours.

consulter en ligne

Cement Industrial Process: Modeling and Optimization

2019.9.9 The crusher specific electrical energy represents the energy consumed by the different elements of the crusher to produce a ton of cement. The major equipment that consume electrical energy at the cement crusher are: main engine with a power of about 4000 Kw, ventilator with a power of the order of 2000 kw and separator

consulter en ligne

Kleemann outlines electric mobile crushing requirements

1 天前 A suitable advanced design of the infrastructure is important for efficient use of electric crushing and screening equipment. Tobias Möß from Wolff Müller GmbH explained the actual energy requirements of the plant and the demand of all already existing consumers should be determined. “How much power is needed on the entire company premises?

consulter en ligne

Energy Efficiency Measurement of Mechanical Crushing

2024.6.28 The efficiency of mechanical crushing is a key metric for evaluating machinery performance. However, traditional contact-based methods for measuring this efficiency are unable to provide real-time ...

consulter en ligne

Crushing and Liberation of Materials by Electrical

The energy consumption by the electrical disintegration is greatly reduced as compared with the ... crushing and grinding equipment breaks the materials into a random pattern from rocks,

consulter en ligne

ANALYSIS OF ENERGY CONSUMPTION OF CRUSHING

analysis of the results shows that taking into account energy consumption, it is better to use two-stage crushing process. For given materials energy consumption in the two-stage crushing process was reduced by 30%. Key words: rock crushing, jaw crusher, crushing efficiency, two stage crushing process 1. INTRODUCTION

consulter en ligne

Energy consumption to crush a metric ton of material at

The crushing equipment is characterized by a significant energy-consuming system during the crushing workflow. ... while the electric power consumption for grinding is on average about 60%, and ...

consulter en ligne

Energy Consumption in Mining Comminution - ScienceDirect

2016.1.1 Energy consumption occurs everywhere in the mining and manufacturing sectors. For relevance in energy consumption, table 1 compares energy consumption for certain parts of the mining sector with other global energy consumption. 142 Jack Jeswiet and Alex Szekeres / Procedia CIRP 48 ( 2016 ) 140 – 145 Table 1.

consulter en ligne

All-electric operation of mobile crushing and screening plants

2024.9.18 In the electrified version, it has an average current consumption of 302 kW per operating hour. The maximum power requirement is 542 kilowatt“, says Tobias Böckle, head of Product Management at Kleemann. “The energy requirement must first be provided by the infrastructure and is ideally met by electricity from renewable sources.

consulter en ligne

9.6: Electrical Energy and Power - Physics LibreTexts

The electrical energy (E) used can be reduced either by reducing the time of use or by reducing the power consumption of that appliance or fixture. This not only reduces the cost but also results in a reduced impact on the environment. Improvements to lighting are some of the fastest ways to reduce the electrical energy used in a home or business.

consulter en ligne

Breaking down energy consumption in industrial grinding mills

2017.1.17 Grinding mills are infamous for their extremely low energy efficiency. It is generally accepted that the energy required to produce new mineral surfaces is less than 1% of the electricity consumed ...

consulter en ligne

>> Next:Types De Broyeurs à Charbon Dans Une Centrale Thermique

- minerai de la machine concasseur de pierre

- petite inde concasseur mobile à vendre

- concassage mobile le venda

- le concassage de pierres Maroc

- fabricant Maroc de vente de broyeur de

- concasseurs dolomie à Centurion

- broyeurs a boulets pour le broyage primaire installes à

- plantes concasseur broyeur à boulets

- laitier de haut fourneau pièces metalliques concasseur

- fabricants de broyeur Indonésie cône concasseur Indonésie cône hydraulique

- balle fabricant de moulin chimie

- conception de processus de machine de concassage minerai

- fournisseur materiel pour la carriere de concasable

- broyeur pour la ferraille et la billette

- concassage brusting de marbre