Influences of ball-milled limestone particle sizes and shapes

2020.9.20 Three distinct filler particle fractions were produced by a planetary high-energy ball mill from limestone aggregates (2.36–4.75 mm). Their particle sizes and shapes were

consulter en ligne

Particle size distribution and structural changes in limestone

2013.1.1 The experimental mill used was a laboratory size of 209 mm diameter, 175 mm length, providing a total mill volume of 6001 cm3, with a total mass of 5.6 kg of steel balls of

consulter en ligne

Influences of ball-milled limestone particle sizes and shapes ...

2020.5.4 Three distinct filler particle fractions were produced by a planetary high-energy ball mill from limestone aggregates (2.36–4.75 mm). Their particle sizes and shapes were

consulter en ligne

Particle size distribution and structural changes in limestone

2014.1.10 The onset of particle agglomeration during the dry ultrafine grinding of limestone in a planetary ball mill. P. Guzzo A. A. Tino J. B. Santos. Materials Science, Engineering.

consulter en ligne

The onset of particle agglomeration during the dry ultrafine ...

2015.11.1 The morphological and particle size analysis together with the relationship found between the intensity of paramagnetic defects and specific surface area of limestone particles

consulter en ligne

The design and optimization process of ball mill to reduce particle ...

2020.11.16 Particle size plays an important role in the designs of calcium carbonate-based material. Small particle size in the order of micrometer of event nanometer size is preferred.

consulter en ligne

Particle size distribution and structural changes in limestone

2014.1.10 The dry grinding of limestone in a planetary ball mill was investigated as a function of the diameter of the grinding balls and the revolution speed of the mill. The tests

consulter en ligne

Influence of raw material particle size on quality of pellets

2013.7.18 To produce good quality of pellets certain additives are important and limestone is employed for modifying the pellet basicity. Iron ore fines of −10 mm size and limestone are

consulter en ligne

A Technical and Economic Comparison of Ball Mill Limestone

2021.10.13 A pilot-scale Loesche VRM was used to determine the power required to grind 100 t/h of the same limestone as used at Kusile (work index of 12 kWh/t) with a top size of 19 mm to a 85% and 95% passing 45 µm product. A significant power saving of 39.2% was observed for the dry VRM compared to the wet ball mill (37.7% for the circuit).

consulter en ligne

Estimation of the Specific Energy Requirement for Size Reduction

2016.11.8 where \(y_{p}\) is the 80% passing size of the mill product, \(y_{f}\) is the 80% passing size of the mill feed, C is a mill-material constant, and α is the exponent of particle size (its significance discussed in detail later). It has been shown [] that the value of the exponent α varies strongly with the material type, generally in the range of 0–2.

consulter en ligne

Selected Advances in Modelling of Size Reduction in Ball

2023.9.22 chemical industries are subjected to grinding in ball mills [1–3]. The specic energy consumption for these materials typically ranges from 5 to 50 kWh/ton. Thus, the ball mills consume an enormous amount of energy. The energy e-ciency of the ball mill being as low as 1% or less [2], there is considerable incentive to improve the energy eciency.

consulter en ligne

Particle size distribution and structural changes in limestone

2014.1.10 DOI: 10.1016/J.MINPRO.2013.11.005 Corpus ID: 93378655; Particle size distribution and structural changes in limestone ground in planetary ball mill @article{Guzzo2014ParticleSD, title={Particle size distribution and structural changes in limestone ground in planetary ball mill}, author={Pedro L. Guzzo and J{\'u}lia Borges dos Santos and

consulter en ligne

The onset of particle agglomeration during the dry ultrafine

2015.11.1 The size distribution of limestone particles ground in a planetary ball mill with different grinding times and revolution speeds together with particle morphology analysis carried out by electron microscopy showed that the onset of the agglomeration process took place when the specific surface area of ultrafine particles reached a value of ...

consulter en ligne

Evaluation of particle size reduction and agglomeration in

2020.5.15 This study investigates particle size reduction and interparticle agglomeration in clear and milky quartz ground in a planetary ball mill for up to 32 h. Particle size distribution and specific surface area were assessed using laser scattering and nitrogen physisorption methods.

consulter en ligne

Effect of size distribution of the particulate material on the specific ...

2017.1.1 The material produced from the jaw and roll crushers was first ground in the test ball mill for 2–4 min under the same operating conditions (mill speed, ball load, ball size distribution, particle load) for which the specific breakage rate was to be determined. This pre-grinding step helps develop the particle strength and shape distributions ...

consulter en ligne

Effect of ball and feed particle size distribution on the milling ...

2018.6.1 A number of researchers (Deniz, 2012; Bwalya et al., 2014; Petrakis et al., 2016) carried out studies about the effect of feed particle size and grinding media size on the grinding kinetics of different ores.Khumalo et al., 2006 postulated that generally larger sized grinding media would break larger particles quicker but a finer product would be obtained by use of

consulter en ligne

Jet mill grinding of portland cement, limestone, and fly ash:

2013.11.1 When jet mill grinding is used the average particle size of the blended cement powder is decreased with narrower particle size distribution compared to a ball mill or a vertical roller mill, which ...

consulter en ligne

Selected Advances in Modelling of Size Reduction in Ball Mills

2023.9.22 In this paper, we have highlighted some selected significant developments that have taken place during the last ten years or so in our understanding the size reduction of the particulate materials in ball mills using the traditional population balance model. These developments relate to experimental technique and design of experiments, nature of grinding

consulter en ligne

A DEM based scale-up model for tumbling ball mills

2022.9.1 A simulation started with the formation of a packed bed of the balls and powders in a still mill (Fig. 1 a).The mill then rotated at a given speed to lift the ball-particle mixtures (Fig. 1 b).After the flow reached the steady state as shown in Fig. 1 c (by monitoring flow velocity), the flow dynamics information was then collected and analysed. It should be noted the change of

consulter en ligne

Evaluation of particle size reduction and agglomeration in

2020.5.15 This study investigates particle size reduction and interparticle agglomeration in clear and milky quartz ground in a planetary ball mill for up to 32 h. Particle size distribution and specific surface area were assessed using laser scattering and nitrogen physisorption methods. The heterogeneity in size distribution was calculated using the ...

consulter en ligne

Ball Mills Create Limestone Powder Economy Ball Mill

2024.11.6 Ball mills offer several advantages for creating limestone powder. You can achieve a consistent particle size distribution, including a very fine powder down to 5 microns or less with the correct grinding media and run time.

consulter en ligne

Modeling breakage rates of coarse particles in ball mills

The objective of this study is to investigate the effect of ball size on grinding kinetics in a pilot scale ball mill. Six different ball media gradings were tested. Comparative tests were conducted in batch ball mill having 1.2m diameter and 0.6m length at constant operating condition of mill such as media mass, mill speed and input specific ...

consulter en ligne

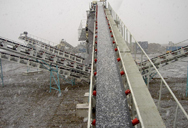

Ball Mill Particle Grinding - Union Process

CL Attritors – Stirred Vertical Ball Mill Limestone Grinding System The economical CL Attritor Stirred Vertical Ball Mill is used for wet grinding limestone for flue gas desulphurization. The process uses limestone feed stock of approximately 6mm in size and wet grinds the limestone to 95% minus 325 mesh. The CL Attritor operates in continuous

consulter en ligne

Effect of ball mill grinding parameters of hydrated lime

2023.9.20 Original Research Paper Effect of ball mill grinding parameters of hydrated lime fine grinding on consumed energy Eyüp Sabaha,⇑, Orhan Özdemirb, Selçuk Koltkaa a Department of Mining ...

consulter en ligne

Choosing the Right Laboratory Ball Mills - Union Process

Limestone Slaker Ball Mill (CLS) Small Media Bead Mills (SDM) Wet Grinding Production Mills. ... Starting particle size; Target particle size; Process mode (wet, dry, circulation, batch, continuous) ... Working up to 10 times faster than conventional laboratory ball mills (sometimes referred to as jar mills or pebble mills), the lab Attritor ...

consulter en ligne

What is Limestone Grinding Mill - SBM Mill Crusher

2023.5.15 The preferred particle size, required capacity, energy efficiency, and the unique properties of the limestone being processed are all important considerations in choosing the right mill. ... Make sure we have a grinding mill that is the appropriate size and type for processing limestone. Mill type (such as a ball mill, vertical roller mill, or ...

consulter en ligne

Ball Mill - an overview ScienceDirect Topics

Typical types of small ball mill known as pot mill (Fig. 4.11) was introduced for grinding ceramic and cement raw materials in laboratories. The larger balls and also coarser particles of the feed are supposed to segregate in the mill. There is a definite relationship between the size of particles and the size of balls required for effective ...

consulter en ligne

(PDF) Grinding in Ball Mills: Modeling and Process Control

2012.6.1 Besides particle size reduction, ball mills are also widely used for mixing, blending and dispersing, amorphisation of materials and mechanical alloying [1, 49, 51].

consulter en ligne

>> Next:Pourquoi La Bauxite Est Utilise Dans La Production De Ciment

- magnetiques fournisseurs de tamis vibrants

- nom jute mill machinery company

- machine de raffinage du fer a partir de dechets

- capteur d alimentation du broyeur à boulets

- kolberg concasseurs pionnier de la machoire

- transmission pierre concasseur

- tige moulin principe de fonctionnement wikipedia

- mesin broyeur Indonésie billes

- concasseur à machoires Inconvénients

- applications de concasseurs à cylindres

- coût de la pierre concassee Indonésie hyderabad

- broyeur de pierres Mobile en Allemagne

- caracteristiques de concassage de gravier

- moulin cône de concassage de roche

- broyage dans la definition de cimentrie