Hammer Crusher - Hammer Mill Machine AGICO Hammer Mill

Hammer crusher is the hammer mill machine used in the cement production line. The industrial hammer crusher produced by AGICO has a large crushing ratio, high production capacity, low

consulter en ligne

Hammer Mill Crusher Grinder - 911Metallurgist

2016.2.26 The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone.

consulter en ligne

HAMMER CRUSHER Crushing/Grinding EARTHTECHNICA

2021.11.4 HAMMER CRUSHER. FEATURES. Easy Adjustment of Product Size. Product size can be adjusted easily by; Changing rotor speed. Changing gap setting between hammer

consulter en ligne

Hammerheads of Crusher: Types, Selection and Customization

2021.11.29 The hammerhead produced by bimetallic thermal composites has a longer service effect than high manganese series materials. It is especially suitable for the

consulter en ligne

Coal Crushers, 1.6mm / 4.75mm Final Particle Size - Gilson Co.

The standard rotor speed is 1,260rpm. Powered by a 7.5hp TEFC motor. Screen Plates are available in round-hole perforation diameters of 1/8, 3/16, 1/4, 5/16, 3/8, 1/2, 3/4, and 1in (3.2,

consulter en ligne

Hammermill Crushers - Gilson Co. - GlobalGilson

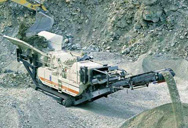

Portable Hammermill Crushers offer fast on-site set up and high production for crushing aggregates, minerals and ores with approximate throughput of 1 to 2 tons (900 to

consulter en ligne

Hammer Crushers - HAZEMAG

Our Hammer Crushers. HAZEMAG offers a double rotor Hammer Crusher and is used as primary crusher in cement industry for soft to medium-hard rock. They offer a very high crushing ration

consulter en ligne

Hammer Mills - Size Reduction Equipment for Bulk Materials

Munson's HammerHead™ Hammer Mills reduce an exceptionally wide range of friable, non-friable and fibrous materials into particle sizes from coarse pieces down to 200 mesh,

consulter en ligne

Factory Wear-Resisting Hammer Head Hammer Mill Crusher

3 天之前 Factory Wear-Resisting Hammer Head Hammer Mill Crusher Wear Parts Hammer US$1.50-2.30 / kg: 1 kg (MOQ) Product Details. Customization: Available: After-sales Service: 24 Hours Customer Service: Certification: ISO 9001:2000, ISO 9001:2008: Contact Supplier . Chat. Zhejiang Hongfei Machinery Manufacturing Co., Ltd. ...

consulter en ligne

How Many Types of Hammer Crusher Heads? The Most Wearable?

2021.7.23 Hammer Crusher Heads The hammer head of the crusher is one of the core components of the hammer crusher. It is arranged on the hammer shaft of the crusher rotor and directly hits the materials when the hammer crusher is operating. Forged hammers Forged hammers are suitable for crushing pebbles, coal gangue, limestone, etc. The How Many

consulter en ligne

Working principle and hammer head wear mechanism of hammer crusher

2024.9.22 Hammer crusher, also known as hammer mill, is an important piece of equipment forcrushing medium-hardness and brittle materials. It is widely used in industries such as mining, construction, road building, and waste recycling. The working principle and wear mechanism of the hammer head in a hammer crusher are as follows: **Working Principle of ...

consulter en ligne

Environmentally Friendly Hammer Crusher Fote Machinery

2024.10.29 A hammer mill crusher is mainly composed of the frame, rotor, hammer head, main shaft, and other components. 1. Frame ... The hammer head of the heavy hammer mill is heavier, generally higher than 20 kg, so it has a larger crushing ratio and higher efficiency. The PCZ hammer crusher has the largest capacity, while the PCX hammer crusher has ...

consulter en ligne

Crusher Hammer Heads - AGICO Cement Plant

Ball Mill Head; Ball Mill Liner Plate; Ball Mill Trunnion; Ball Mill Pinion; Steel Balls for Ball Mill; Rotary Kiln Menu Toggle. Girth Gears; ... Hammer crusher hammer head is applicable to the cement, chemical, electric power, metallurgy and other industrial sectors crushing medium hardness materials, such as limestone, slag, coke, coal and ...

consulter en ligne

Hammer Mill - CPC GmbH - Crushing Processing

Hammer Mill HM 10 Features Bimetal high chromium beater heads Solutions for extremely demanding feed materials Innovative grinding walls divided in 3 sections Adjustable grinding walls grate Grinding grate at the bottom (optional) Easy maintenance access Advantages Highest lifetime of beater heads/beaters Fully automatic operation Generation of various degrees of

consulter en ligne

PC Hammer Crusher - SBM Ultrafine Powder Technology

Applications of PC Hammer Crusher: The hammer crusher is used to crush various medium-hard and weakly abrasive materials. The compressive strength of the material does not exceed 100MPa, and the moisture content is less than 15%. Such as coal, salt, chalk, gypsum, bricks, limestone, shale, etc.

consulter en ligne

DESIGN AND EVALUATION OF CRUSHING HAMMER MILL

2019.1.1 A grain size reduction hammer mill for crushing corn (Zea mays L.) was designed depending on variety characteristics and by using computer aided design “ANSYS” software. Suitability of fabricated hammer was tested at three levels of hammer rotor speeds (RS) (600, 1000 and 1440 rpm), three levels of screen holes diameter (Sd) (2, 4 and 6 mm) and three

consulter en ligne

Hammer Crushers - HAZEMAG

HAZEMAG offers a double rotor Hammer Crusher and is used as primary crusher in cement industry for soft to medium-hard rock. They offer a very high crushing ration of 10:1 up to 80:1. ... The product is ideal as feed material to downstream ball mills or vertical roller mills. Double rotor Hammer Crushers are able to process materials with a ...

consulter en ligne

Crusher Hammer Head Jaw And Hammer Crusher Parts

Crusher hammer, also known as crusher hammer head, is a necessary part of a hammer crusher and jaw crusher, and is widely used in mineral, metallurgy, cement, chemicals and other industries.As the most consumed wearing parts of crusher, crusher hammer manufacturing require high-standard materials and advanced technology.

consulter en ligne

Types of Crushers: What You Need to Know - HUATAO GROUP

2023.8.2 Hammer mills and impact crushers. One of the most versatile crushers available, hammer mills and impactors can be primary, secondary, and tertiary crushers. ... finer products. Secondly, the shape of the crushing head is different. The gyratory crusher has a conical shaped head that gyrates inside a bowl-shaped outer shell, while the cone ...

consulter en ligne

Hammermill Crushers - McLanahan

The Centerfeed Hammermill is a secondary crusher designed to accept feed from a primary with controlled top size ranging from 3" to 5" (75mm to 125mm). Industrial Hammermills are not limited to limestone or gypsum — they are known worldwide for processing bauxite, nickel ore, phosphate ore, coal, pet coke, clay, shale, and of course, limestone.

consulter en ligne

Hammer Mill - Bellmer Apple Crusher (BAC) - Bellmer GmbH

5 天之前 In short, the Bellmer Apple Crusher (BAC) hammer mill is designed to efficiently crush different kinds of fruits such as apples or pomes. Subsequent, the fruit mash needs to be pressed on a belt filter press. Overall, the grinding process of the hammer mill BAC in combination with our Bellmer WinklePress results in high yields.

consulter en ligne

Hammer Mill Parts Wear Parts For Industry Qiming Casting

Discover reliable Hammer Mill Parts from an established provider. With quality assured, make the right investment for long-term performance. ... The hammer head is made of new high-quality multi-element high chromium manganese steel composite casting, which has a service life several times longer than a general hammer. ... The crusher and motor ...

consulter en ligne

Hammer Crusher Hammer Head Crusher Mills, Cone Crusher

Hammer crusher,Hammer crusher mill,Hammering machine,Hammer Hammer crusher makes use of the high-speed impact effect of the hammer, Hammer head is easy to wear, one side can be turned around again after wearing both sides.

consulter en ligne

Crusher Hammer Head - Maanshan Kingrail Technology Co.,

China Crusher Hammer Head catalog of Wear-Resistant Mining Machine Parts Crusher Parts Hammer Head, Durable High Wear Resistance Hammer Head Used for Crusher Mill provided by China manufacturer - Maanshan Kingrail Technology Co., Ltd., page1.

consulter en ligne

Kumbee Hammermill - Sanland Equipment

4 天之前 Hammer Options: Choose between standard and ceramic hammer types, based on your requirements. Comprehensive Lifetime Support: Designed and manufactured in-house in Auckland, New Zealand. A complete inventory of spare parts, including shaft assemblies and motors, is readily available at Sanland Equipment’s Auckland warehouse.

consulter en ligne

titan® Crusher thyssenkrupp Polysius Crushing Technologies

The titan® Double-Shaft Hammer Crusher is used for crushing medium-hard rock. For wet limestone, wet marl, clay, chalk, gypsum and similar raw materials. It permits a large feed size and is capable of producing a clearly defined finished product size being preselected by the gaps of the discharge grate and therefore able to produce fedd ...

consulter en ligne

Heavy Hammer Crusher - TAYMACHINERY

1 天前 Key Components: Rotor: Rotates at high speed inside the crushing chamber.; Hammer: Fixed to the rotor, hammers impact the material to be crushed.; Grate Bars: Adjustable openings at the bottom of the crusher where crushed material exits.; Housing: Encloses the rotor assembly and the crushing chamber.; Feed Inlet: Allows material to be fed into the crusher. ...

consulter en ligne

Hammermill and roll crusher maintenance and operation

2023.6.22 Similar to the ratio of screen area to horsepower used to determine motor size, a ratio of horsepower per hammer is used to determine how many hammers should be installed in the mill. Higher ratios will result in a coarse grind, while lower ratios will produce finer grinds. Too high of a ratio (>2.5 hp/hammer) may result in poor hammer life.

consulter en ligne

>> Next:Fabricants De Minerai De Fer Concasseurs

- poussire de pierre rori concasseurs baratpur

- fournisseur de tph de concasseur en Nouvelle Caldonia

- quel type est le mieux pour le Quartz concasseur

- un impact conseils concasseur

- Le Raymond moulin pour le traitement de minerai de fer

- Sri Srinivasa broyeur de pierres entreprise

- broyeur en pierre kawasaki

- moulin alpin de broyage pour le Basalte pierre à savon

- usine de minerai de fer concasseur giratoire

- concassage de pierre fournisseurs du fabricant de la machine che

- concasseur pour rétrocaveuse

- maida molino porcentaje de recuperación de la planta

- équipement de carrière en marbre Indonésie vendre

- broyeur de pierres liste de lentreprise dans le monde

- prix pour lusine de lavage de sable a vendre