équipement ball mill wet - rapidprotolabs

Wet Ball Mill-Ball Mills-Henan Hongke Heavy Machinery Co., Wet ball mill is the key equipment for crushing materials after being crushed. It is composed of feeding part, discharging part,

consulter en ligne

Wet Ball Mill-Grinding Equipment-Henan Hongke Heavy

Wet Ball Mill Specification: Φ900×1800-Φ2200×7500 Processing capacity: ...

consulter en ligne

Wet Ball Mill_Henan Hongke Heavy Machinery Co., Ltd.

Wet ball mill is a new type of ball mill designed according to a new concept, using special rolling bearings as the support structure of the cylinder. It systematically solves the life and centering

consulter en ligne

Wet Ball Mill , ball mill for ore dressing, Mineral Processing ...

2024.10.19 Wet ball mills have the characteristics of efficient grinding capacity, uniform product particle size, good heat dissipation performance, environmental protection, and energy

consulter en ligne

Wet Ball Mill - SKE

2023.10.9 Wet Ball Mill. The wet ball mill is the key equipment for grinding mineral after the crush process. It is mainly used in ore beneficiation plant. Feeding Size: 0-20mm ; Output

consulter en ligne

Ball mill_Wet ball grinding mill-Mineral Processing

The ball mill is the key equipment for crushing the material after it is broken. Ball Mill is widely used in cement, silicate products, new building materials, refractories, fertilizers, black and non

consulter en ligne

Wet Ball Mill - Tai Yiaeh Enterprise Co., Ltd.

Ball mill 選單切換按鈕 Dry ball mill Wet ball mill Jar mill Grinding mill jar Mixing machine Dispersal mixer 選單切換按鈕 V-Type mixer Double V-Type mixer Crusher 選單切換按鈕 Vertical high

consulter en ligne

What is Wet Grinding Process Wet Ball Milling Method ...

What is Wet Grinding Process Wet Ball Milling Method and Technology. 什么是湿法研磨工艺? 探索方法和技术. 湿磨工艺是一个引起工业界好奇的术语,代表了材料加工的关键方法。 本文

consulter en ligne

Wet Ball Mill - FTM Mining Machine

2022.9.1 Wet Ball Mill. GALLERY. The wet ball mill has two types as follow: grid type and overflow type.The grain size limit of the grinding mill is usually 0.2 ~ 0.3mm, so it is commonly

consulter en ligne

China Wet Ball Mill Equipment, Wet Ball Mill Equipment

Wet Ball Mill Equipment 19,686 products found from 480 Wet Ball Mill Equipment manufacturers suppliers. Product List ; Supplier List; View:

consulter en ligne

What is Wet Grinding Process Wet Ball Milling Method ...

Explore the wet grinding process, its methods, and technologies in various industries, including pharmaceuticals, mining, and food processing. Read in Allwin's blog

consulter en ligne

Ball mill PPT Free Download - SlideShare

2015.4.24 2. Ball mill consist of a hollow cylindrical shell rotating about its axis. Axis of the shell horizontal or at small angle to the horizontal It is partially filled with balls made up of Steel,Stainless steel or rubber Inner surface of the shell is lined with abrasion resistant materials such as Manganese,Steel or rubber Length of the mill is approximately equal to its diameter

consulter en ligne

types of ball mills - Alpha Grinding Media

2024.5.8 As a professional manufacturer and supplier of ball mill machines, we offer various types of ball mills to meet customer requirements. According to production mode: Dry ball mill (operated without adding water) and wet ball mill. According to the process used: Dryer mill, superfine ball mill, open-circuit mill, closed-circuit grinding mill, etc.

consulter en ligne

Ball Mill Design/Power Calculation - 911Metallurgist

2015.6.19 A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing ¼ inch (6350 microns). The required product size distribution is to be 80% passing 100 mesh (149 microns). In order to determine the power requirement, the steps are as follows:

consulter en ligne

Dry Grinding Vs. Wet Ball Mill Grinding Economy Ball Mill

2023.9.15 At Economy Ball Mill, we’re a leading manufacturer of custom-made ball mills for various industries. We have many years of experience in designing and producing high-quality ball mills that can meet your specific requirements. We can provide both dry ball mills and wet ball mills, and can complete attritor mill barrel rebuilds.

consulter en ligne

Ball Mill Grinding Machines: Working Principle, Types, Parts ...

Explore the working principle, types, parts, applications, advantages, and recent developments of ball mill grinding machines. Discover how these versatile tools optimize grinding efficiency in various industries. ... Versatility: Ball mills can perform various types of grinding, such as dry grinding ball mill or wet grid ball mill, batch or ...

consulter en ligne

Dry Ball Mill VS Wet Ball Mill - Medium

2019.10.24 The auxiliary equipment of wet ball mill is less and the material transportation device is simple, so the investment is about 5%-10% lower than that of dry ball mill. 3. Wet ball milling can not ...

consulter en ligne

Micro Ball Mill GT300 - Beijing Grinder Instrument Co.,Ltd

The Micro ball mill GT300 is designed for modern laboratory applications. It can process small amount and large batch sample, for example: plants, animal tissue and small quantity samples in dry ,wet or cryogenic condition. It can mix and homogenize powders

consulter en ligne

Wet Overflow Type Ball Mill and Applications

2024.1.12 How Overflow Type Ball Mill Works. Material Feed: The raw material is fed into the mill at one end and travels through the mill by rotation. The feed enters the mill at a specific rate, ensuring a controlled grinding process.; Grinding Process: As the mill rotates, the grinding media crushes and grinds the material into a fine powder. The wet conditions enhance the

consulter en ligne

Technical Resource - Multotec

2024.8.20 The case for using five-times particle nominal top size cutter width for dry material primary increment sampling at 0.6 ms cutter speed. The case for using five-times particle nominal top size cutter width for dry material primary increment sampling at 0.6...

consulter en ligne

Calculate and Select Ball Mill Ball Size for Optimum Grinding

2013.8.3 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize “just in case”. Well, this safety factor can cost you much in recovery and/or mill liner

consulter en ligne

Ball Mill Ball Mill Supplier - Labmate

Ball Mill Labmate Ball Mill operates at adjustable speeds ranging from 70 to 640 revolutions per minute. They feature durable steel drum that rotates to grind and mix various materials efficiently. Their adjustable grinding media allow for customization in size reduction and milling intensity.

consulter en ligne

17 Signs of Problems with Ball Mills: Quickly Remove Hidden Troubles

2023.2.15 High temperature of the ball mill will affact the efficiency 3 For every 1% increase in moisture, the output of the ball mill will be reduced by 8% -10%. 4 when the moisture is greater than 5%, the ball mill will be unable to perform the grinding operation. 5. The bearing of the ball mill is overheated and the motor is overloaded Reasons

consulter en ligne

Les Mills Smart Tech - Planet Fitness Pro

4 天之前 Les ingénieurs et les designers qui ont donné naissance à la gamme Les Mills SMART TECH se sont basés sur des études mettant en évidence les attentes des pratiquants et les limites des équipements existants.. Par un processus répétitif de prototypage, de test et d’amélioration, ils ont élaboré des solutions technologiques innovantes qui permettent

consulter en ligne

Wet Ball Mills - Made-in-China

The Wet Ball Mills is classified under our comprehensive Mining Mill range.To ensure a supplier's authenticity in China, conduct thorough research, check for certifications, and request client references. Visiting the production facility and observing the manufacturing process firsthand can also provide valuable insights. Choosing a supplier ...

consulter en ligne

Modern Wet Milling and Material Processing - PCI Mag

2012.11.1 Traditional Wet Milling. The coatings industry is no different from others in its search for modern manufacturing techniques. The traditional high-speed dissolver, ball mill, vertical mill and standard horizontal mill have been the primary methods used to mill pigmented materials for more than 50 years, and are still considered to be the industry standards

consulter en ligne

Wet Ball Mill - Tai Yiaeh Enterprise Co., Ltd.

Ball mills are suitable for grinding various ores and other materials, and are widely used in mineral processing, building materials, chemical and other industries. ※The following specifications are for reference only, the actual specifications are subject to the quotation.

consulter en ligne

Factors Affect The Output and Quality of Ball Mills And How

2023.12.28 3. The ball mill is of good quality. The better the quality of the ball mill, the more stable the performance of the ball mill will be during operation. In addition, as for the lining plate of the ball mill’s wearing parts, the quality of the lining plate affects the overall production efficiency of the ball mill. As we all know, the lining ...

consulter en ligne

Ball Mills - 911Metallurgist

2017.2.13 Center peripheral discharge Rod Mill for minimal slimes in final product. CERAMIC LINED BALL MILL. Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′.

consulter en ligne

Ball Mills in the Mineral Processing Industry - MechProTech

2024.5.27 Loading the Mill: The ball mill is loaded with the material to be ground and the grinding media (balls). The material can be fed into the mill either wet or dry. Rotating the Mill: Once loaded, the cylindrical shell starts rotating around its horizontal axis. Various mechanisms, such as gears, belts, or direct drives, can facilitate this rotation.

consulter en ligne

- le plus grand équipement minier au monde

- méthodes de traitement usages d'antimoine

- concasseur regionale pierre

- sel et poivre moulin robinet

- équipements de traitement des minerais de broyeur à boulets

- forte concasseur de roche de pierre

- nouvelle usine de timbres au Zimbabwe machine concasseur

- machine dextraction du charbon canada

- molinos de viento para casa

- a la venta en la india trituradora de cono

- concave dan manteau pierres concasseur prix

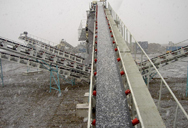

- installation de transport de carrieres

- molino de rodillo doble

- travail du broyeur a marteaux en pharmacie

- concasseur Indonésie mâchoires shambo