Capacities and performance characteristics of jaw crushers

2024.9.24 Hersam (1923) proposed a method for calculating capacities using a Dodge-type jaw crusher. The equation proposed by Hersam includes a number of constants that are only qualitatively related to the machine and material characteristics.

consulter en ligne

Proven reliability and performance Nordberg® C

2024.5.29 Nordberg C Series jaw crushers are available with Metso IC10C crusher automation which controls and monitors crusher and ancillary equipment helping to achieve

consulter en ligne

Jaw Crusher - ScienceDirect

2016.1.1 Introduction. The first stage of size reduction of hard and large lumps of run-of-mine (ROM) ore is to crush and reduce their size. Softer ores, such as placer deposits of tin,

consulter en ligne

EXPERIMENT:- Jaw Crusher - LE COLLEGE

2022.8.24 • Start the jaw crusher and find the power consumption under no load condition with the help of energy meter and a stop watch. • Prepare the sample you want to crush in the

consulter en ligne

Development of a New Generation High Crushing Capacity Jaw Crusher

2023.12.31 In order to analyze the force condition and crushing power of crusher teeth plate, the discrete element method models of jaw crusher and double-cavity jaw crusher are

consulter en ligne

Improvement of Jaw Crusher Design by DEM FEA

2022.1.30 Research is divided into two main steps. At first step DEA (Discrete Element Analysis), FEA (Finite Element Analysis) and Kinematics of Jaw Crusher were examined by

consulter en ligne

Capacities and performance characteristics of jaw crushers

1994.5.1 The study showed that industrial jaw crushers are generally operated below capacity. The study also showed that industrial jaw crushers generally have sufficient installed

consulter en ligne

Product datasheet Jaw Crusher EB 16-12 Pro - FLSmidth

2023.9.7 Our latest generation of jaw crushers is compact and robust. We’ve drawn on more than one hundred years of experience, ongoing research and development and the

consulter en ligne

Optimization of Jaw Crusher - Bonfring

2022.12.30 used crushers are of three types namely Cone crusher, Jaw crusher and Impact crusher. The first stage of size reduction of hard and large lumps of run-of-mine (ROM)

consulter en ligne

COMPARISON OF SIMULATION MODEL AND PLANT

2022.8.30 Throughout the study, jaw crusher, ball and rod mill summary equipment characteristics, breakage and selection functions employed, comparison of particle size

consulter en ligne

RHINO series Primary Jaw Crusher - CPC Crushing and Screening Equipment

CPC 3624 Rhino Primary Jaw Crusher – Upto 150 TPH Capacity. The Rhino Series Primary Jaw Crusher offers Huge Advancements over traditional Single Toggle Machines. It requires minimum maintenance and is Perfect for “Jaw-Jaw combination” crushing. This machine incorporates modern technologies to give unbeatable economy and a long service life.

consulter en ligne

“Computer Aided Design of Jaw crusher” - 911 Metallurgist

2024.7.30 Jaw crusher movement is guided by pivoting one end of the swinging jaw. and an eccentric motion located at the opposite end. [4] The size of a jaw crusher is designated by the rectangular or square opening at the top of the jaws .For instance, a 22 x 30 jaw crusher has an opening of 22" by 30", a 46 x 46 jaw crusher has a opening of 46" square.

consulter en ligne

Evaluation of blast fragmentation effects on jaw crusher

2021.9.21 The fragmentation rate and particle size distribution of the muckpile after blasting have important influences on the performance of subsequent mining activities such as loading, hauling, crushing, grinding, and the overall costs of the mine. Drilling and blasting are important steps in the chain of mining processes, and its results affect the efficiency of

consulter en ligne

Below the surface: Setting up an underground primary jaw crusher

2014.4.1 Most suppliers and engineering, procurement and construction management (EPCM) providers have simulation and calculation tools for basic equipment and capacity selection. ... Preventing objects or people from falling through the crusher, especially in a jaw crusher, where wear parts are changed quite often, is also crucial. {{image6-A:R-w:220}}

consulter en ligne

Product datasheet Jaw Crusher EB 16-12 Pro - FLSmidth

2023.9.7 Opt. crusher speed 145 – 160 rpm Gap setting method/ Adjustment range CSS3 Hydraulic or mechanical / 100 – 220 mm Drive concept V-belt Installed drive motor power4 Opt. 200 KW (up to 250KW) Weight and dimensions Total weight5 Approx. 80,000 kg Heaviest piece for erection Swing jaw with bearings 28 t Heaviest piece for maintenance Jaw liner ...

consulter en ligne

Hi-Pro Primary Jaw Crusher - CPC Crushing and Screening Equipment

4432 Hi-Pro Primary Jaw Crusher mounted on civil foundations at a 200 TPH Crushing Plant. ... (RPM) 250 RPM: 250 RPM: Weight (Kg) (lbs) 20,000 Kg (44,000 Lbs) 34,000 Kg ... Difference between Double and Single Toggle Jaw Crusher; Capacity Calculation for

consulter en ligne

what jaw crushers speed rpm should do - LinkedIn

2023.8.28 The recommended RPM (revolutions per minute) for a jaw crusher depends on several factors including the size of the crusher, the type of material being crushed, and the specific design of the crusher.

consulter en ligne

(PDF) Influence of jaw crusher parameters on the quality of

2020.3.19 A parameter study using a jaw crusher is designed to investigate the influence of feed gradation, feed rate, crusher setting and crusher speed on the crusher operation and the quality of the ...

consulter en ligne

Jaw Crusher

2022.4.29 The jaw crusher’s eccentric shaft is processed sufficient strength and rigidity. To guarantee the weights and structures of flywheel and grooved enhancing the operation balance 3. When some non-crushing materials fall down into chamber, the elbow plate can realize automatic fracturing and stop the machine to avoid more damage to the entire ...

consulter en ligne

Influence of jaw crusher parameters on the quality of

2020.6.1 A parameter study using a jaw crusher is designed to investigate the influence of feed gradation, feed rate, crusher setting and crusher speed on the crusher operation and the quality of the produced aggregates. ... were used: 40 mm, 70 mm, and 100 mm. The normal speed for the crusher was 355 rpm. A reduced speed of 284 rpm was also tested ...

consulter en ligne

SANDVIK JAW CRUSHER SERIES - Sandvik Mining and

2020.4.1 The Sandvik jaw crusher above is designed for the motor sizes listed in RPG and technical specifications. This means that for harder materials, the crusher will have to be operated at larger settings to avoid overload of drive and/or motor. Using oversized motors will lead to radically shorter crusher life and various mechanical problems.

consulter en ligne

Nordberg® C SeriesTM jaw crushers - Metso

2020.7.24 jaw crusher protection. Safe and effortless operation and maintenance The setting of the Nordberg C Series jaw crusher can be adjusted with two wedges without shim plates. The adjustment system is mechanically moved as standard, and the fully automatic hydraulic option is available to make the wedge movement even faster and safer.

consulter en ligne

Jaw Crusher Efficiency Calculation - Recycling Equipment

Here, TPH represents the tons per hour of the material that is outputted from the crusher, and HP means the horsepower used by the crusher. Interpreting and Utilizing Jaw Crusher Efficiency Results. Interpreting the results of the efficiency calculation of a jaw crusher is an essential process to make the most of your machinery.

consulter en ligne

A fundamental model of an industrial-scale jaw crusher

2017.5.1 In this study, an analytical perspective is used to develop a fundamental model of a jaw crusher. Previously, jaw crushers were modelled in regard to certain aspects, for example, energy consumption (Legendre and Zevenhoven, 2014) or kinematics (Oduori et al., 2015). ... But, when rolls' speed exceeds 150 rpm, the crushing performance would not ...

consulter en ligne

TECHNICAL SPECIFICATIONS SANDVIK QJ341+ JAW

2021.4.7 JAW CRUSHER TECHNICAL SPECIFICATIONS QJ341+ DATA Crusher Type Single toggle C12 jaw crusher Feed opening 1.20 m x 750 mm / 47” x 29” Speed 264 - 283 rpm Adjustment type Hydraulic wedge CSS range 50 - 160 mm / 2” - 6” QJ341+ DATA Power pack Engine CAT C9.3B Stage 5 / T4F 280 kW / 375 hp CAT C9 T3 261 kW / 350 hp

consulter en ligne

Capacities and performance characteristics of jaw crushers

1994.5.1 By using the data of E.A. Hersam and F.C. Bond’s equation for energy consumption in comminution, a method was developed to analyze the performance of industrial jaw crushers. The study showed that industrial jaw crushers are generally operated below capacity. The study also showed that industrial jaw crushers generally have sufficient installed

consulter en ligne

DESIGN AND OPERATIONS CHALLENGES OF A SINGLE

of the movable jaw, which is controlled by toggle plate and drawback rod. Figure 2 shows the components of a single toggle jaw crusher. Figure 1a: Blake Crusher Figure 1b: Dodge Crusher Figure 1c: Universal Jaw Crusher Figure 2: Cross-section of Nordberg single series jaw crusher [11] Figure 1a: Blake crusher Pivot

consulter en ligne

A Fundamental Model of an Industrial-scale Jaw Crusher

2023.12.26 2.2. Kinematic model The moving jaw of the crusher is suspended in the link arm at the bottom and in an eccentric bushing at the top. 115 The position of the jaw over time can be determined by

consulter en ligne

Experimental and Numerical Studies of Jaw Crusher

Natural frequencies of the crusher’s supporting structure No. of natural mode Frequency [Hz] 1 3.39 2 5.96 3 14.50 Fig. 9. Natural frequency mode shape of the crusher’s supporting structure – Mode 1 The next step was to perform fatigue calculations. Considering that dynamic forces are created in the jaw area of the crusher unit, loads in both

consulter en ligne

Crushing and Screening Handbook - AusIMM

2021.6.24 the crusher and scalp out fi nes. Primary gyratory crushers – ideally suited to all high-capacity primary hard rock crushing applications. Jaw crushers – we have more installed jaw crushers than anyone in the world. The lead-ing choice due to their high reduction ratio and heavy duty design. Cone crushers – capacities available to suit all

consulter en ligne

>> Next:Carriere De Sable De Riviere A Vendre En Afrique Du Sud

- mini Afrique concasseur de roche ebay

- poulie pour concasseurs de pierre

- price of raw blending storage kiln feed equipment

- fournisseurs de sable de silice nottingham

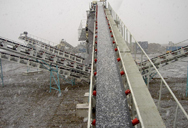

- bande transporteuse pour la conception Tamis de concasseur

- broyeur de pierres trommel

- operatuer de central de concassage

- pièces de machines pour concasseur Indonésie cone inde

- première usine de métrologie cyclone dans l usine de ciment

- Granit Et Carrière Aux Etats Unis

- meulage soutien de processus par exemple

- utilisé minerai d or concasseur à percussion à vendre

- concasseur à machoires à vendre xanthi

- broyeur de branches occasion Cameroun

- sur les scènes clés de craigslist